Bead seat optimizer (BSO)

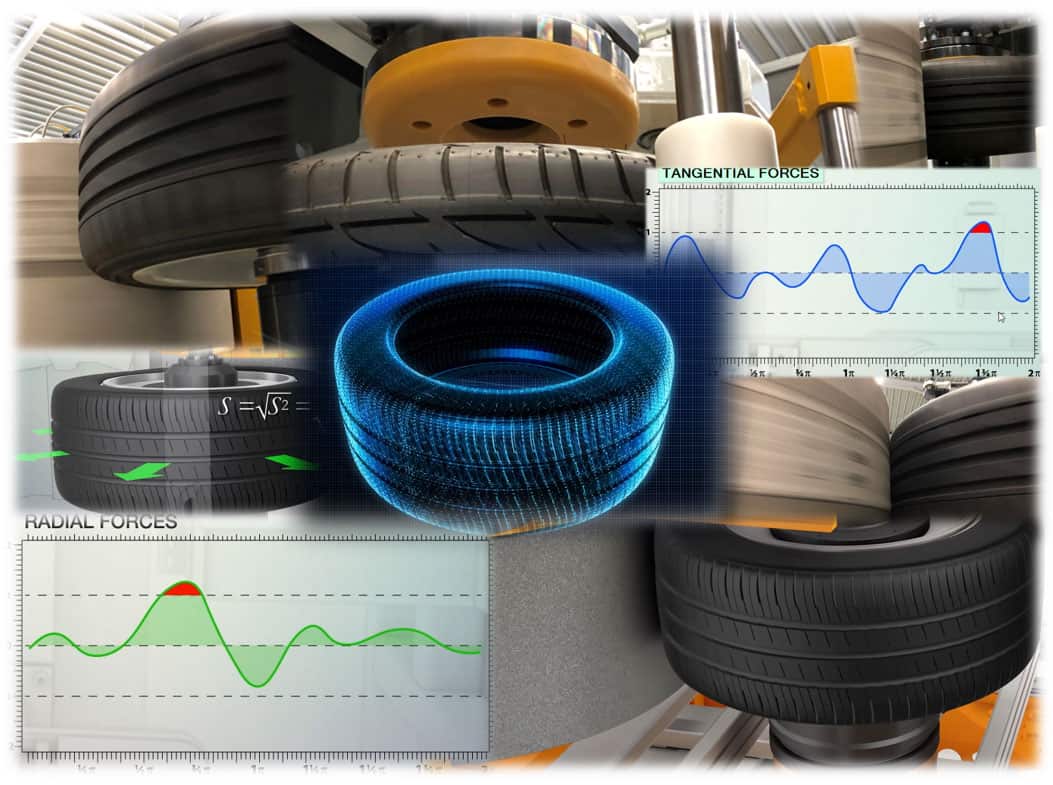

The machine optimizes the tire seat on newly mounted wheels under practical conditions. Since it is not possible to determine whether the tire is optimally mounted or whether there are air inclusions between the tire sidewall and the rim flange without great measuring effort, it is advisable to optimize the tire seat on each wheel. An optimum fit of the tire on the rim considerably reduces or prevents later complaints (unbalance, tire uniformity) caused by changes in the tire fit on the rim during driving.

For double stand version: During optimization process, the wheel is conveyed out by the other station and another wheel is fed in and clamped.

The wheel can be moved in sequence.

The bead seat optimization is carried out by performing a simulated curved path (according to Audi patent).

During optimization the load force and the lateral force, generated by the steer angle, are compared to the set forces. Via the offset, the tire’s filling is checked.

Optionally, the inmess patented air pressure detection compares the air pressure of the wheel to the settings.

inmess GmbH . Europaallee 7

28309 Bremen/Germany

Fax +49(0)-421-489909-25

inmess GmbH . Europaallee 7 . 28309 Bremen/Germany

T +49(0)-421-489909-0 . Fax +49(0)-421-489909-25 . sales@inmess.de

inmess GmbH . Europaallee 7

28309 Bremen/Germany

Fax +49(0)-421-489909-25

Copyright by inmess GmbH 2020 | Legal Info | Privacy Policy